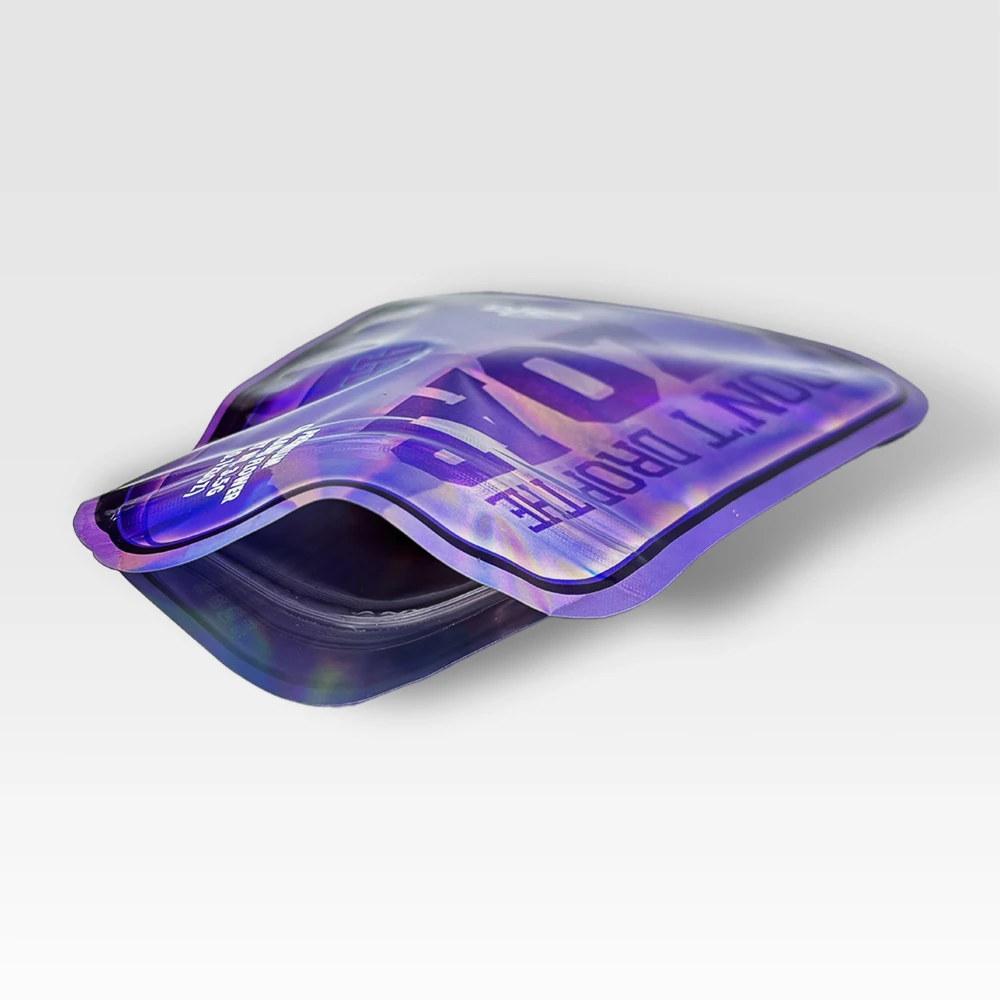

Custom Pouches

Child-Resistant Zipper Pouches for Cannabis: Packaging Regulations in the U.S.

Problem: Kids can access cannabis packaging. Agitation: state rules are growing stricter. Solution: CR zipper pouches help reduce risk and simplify compliance.

This piece explains what CR packaging means in the U.S., how rules vary, and why brands should act now. It outlines core requirements and practical considerations for compliant CR zippers.

Transition: The path is layered, and no single zipper fits every state. Read on to understand the basics, what varies, and how to prepare your packaging strategy.

LOOP START

Is There One Zipper That Works in All States?

Problem: No single zipper fits every state. Agitation: rules differ and some call for extra features. Solution: brands must map requirements and choose adaptable packaging.

From years of work in this field, I’ve learned there is no universal zipper. Child-resistance is defined by testing standards like PPPA and ASTM, yet state rules layer on more requirements such as labeling, symbols, and design restrictions.

PPPA and ASTM testing explained

In practice, PPPA sets a baseline for safety. I see testing focus on opening effort and tamper evidence. ASTM tests add nuance by involving real users in multiple cycles. The tests measure whether a typical adult can open the package while a child cannot within a reasonable time. I must document the protocol, pass rates, and device details. The result is safety plus buyer trust. Yet tests cost time and money. I look for CR zippers with solid test data and clear labeling options. I also watch how tests affect your product’s design, including tamper-evident features and the choice of materials.

State-by-state variations you should know

States vary on CR performance for edibles, symbols, and labels. Some require exit bags or limit certain plastics. Others demand sustainability or recyclability rules. Some ban child-attractive visuals or colors. These differences create a compliance matrix I must manage. I encourage mapping each state’s rules to product SKUs. Even with a certified zipper, I still verify per state, because a feature that helps one state may hurt another. I recommend a phased launch approach to test how packaging performs under different regulations. Keeping a dynamic spec sheet helps teams stay ready for rule changes.

Practical takeaways for brands

First, define a core safety baseline: CR + tamper-evident + resealable. Second, choose zippers with strong test data and clear labeling options. Third, build a state-by-state compliance map linked to SKUs. Fourth, design to avoid child-attractive visuals and use opaque materials. Finally, keep supplier agreements flexible to allow updates as laws change.

| Topic | Key Points |

|---|---|

| Core requirements | CR + tamper-evident + resealable; opacity helps protection. |

| Testing standards | PPPA baseline; ASTM adds user-based validation. |

| State considerations | Edibles, symbols, exit bags, plastics, sustainability vary. |

| Brand actions | Map rules, stay flexible, verify per state, maintain real data. |

LOOP END

CR zipper pouches reduce risk and help ensure compliance across states, but no single solution fits all.