Freshness Is a System: Barrier + Valve + Seal

Great coffee packaging isn’t one feature—it’s how materials, degassing, and sealing work together. A strong barrier slows oxygen and moisture ingress, the right valve manages CO₂ release, and a reliable seal window keeps performance stable on real production lines.

Industry Pain Points & Challenges

Freshness Drops Fast (Oxygen + Moisture)

Even small oxygen or moisture exposure can dull aroma, flatten flavor, and shorten shelf life.

CO₂ Swelling & Valve Mis-match

Freshly roasted coffee releases CO₂—wrong valve or structure can cause bloating, leaks, or complaints.

Seal Failure Under Real Handling

Heat sealing is sensitive to dust, oils, and process swings—tiny micro-leaks become returns in transit.

Shelf Impact vs. Online Presentation

Crowded shelves and thumbnails need strong visuals—if the bag slouches or scuffs, it loses trust fast.

Compliance & Label Space Pressure

Origin, roast date, barcode, and required info compete for space—layout mistakes can delay retail onboarding.

Small-Batch Launch & Fast Turns

Seasonal blends and new SKUs need quick sampling and flexible runs—slow packaging cycles miss the window.

Market Trends & Growth Insights

Not Sure Which Coffee Packaging Format to Choose? Start Here

We’ve grouped the most common coffee packaging types by use case—whole beans, ground coffee, single-serve, retail display, and shipping—so you can compare quickly.

Stand-up Pouches

A retail-friendly format for whole bean or ground coffee with strong shelf presence and easy storage.

Flat Bottom Valve Bags

Upright, premium shelf look with a degassing valve—releases CO₂ while helping protect aroma.

Side Gusset Valve Bags

A classic high-fill coffee format with a degassing valve—supports CO₂ release and stable carton packing.

Flat Pouches

A simple format for sample packs, drip coffee, or smaller retail sizes.

Sachets / Stick Packs

Single-serve convenience for instant coffee, sugar/creamer, or trial bundles.

Folding Cartons

Retail-ready paper cartons for protection and shelf presentation—great for kits, gift sets, and boxed products.

Gift Boxes

Premium unboxing boxes for gifting and high-value items—designed for a strong first impression and organized inner packing.

Labels & Stickers

For compliance info, batch coding, barcodes, and quick SKU differentiation.

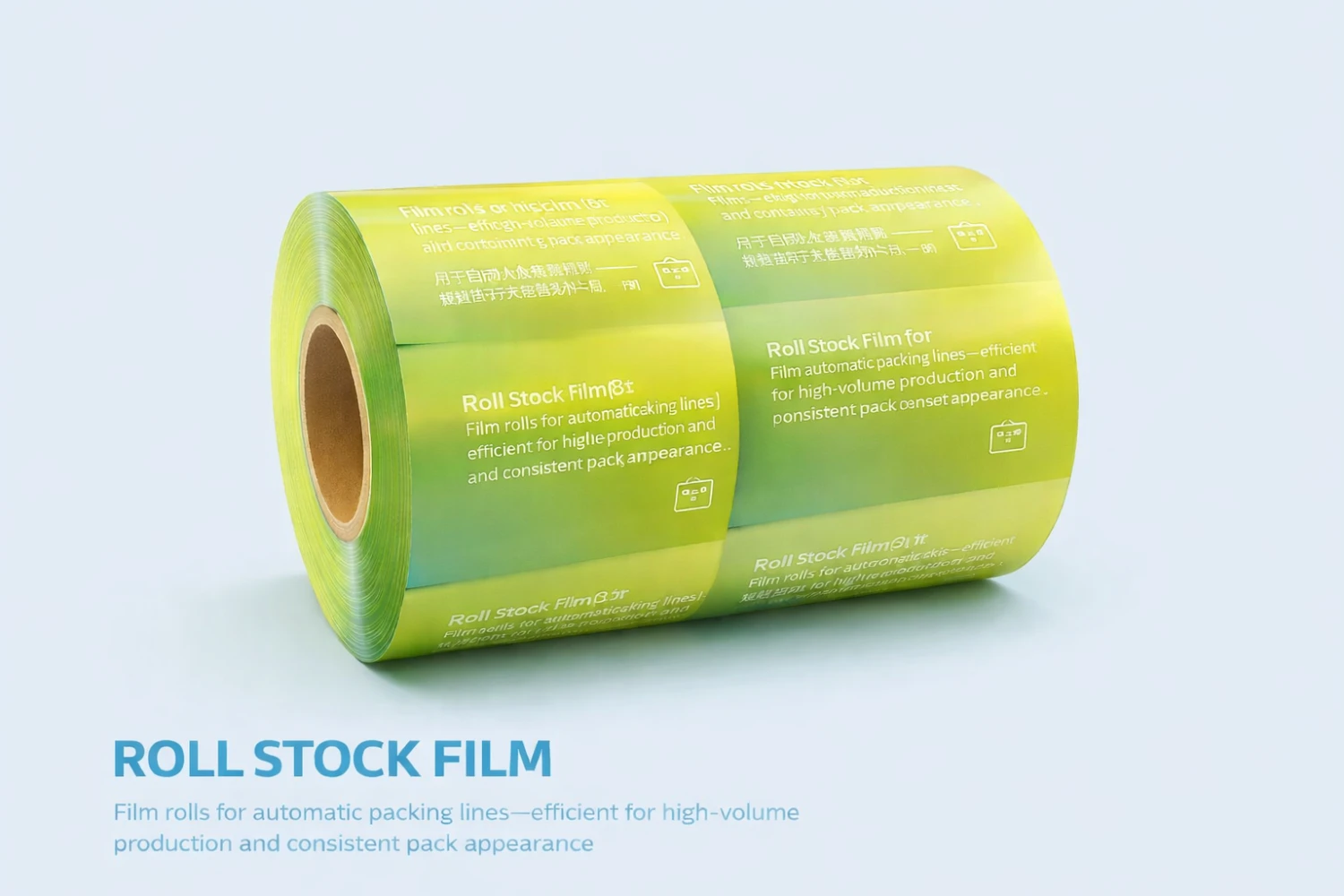

Roll Stock Film

For automatic packing lines—ideal for high-volume single-serve or sachet production.

Tell us your coffee type (bean/ground/single-serve), pack size, and sales channel.

We’ll recommend a practical packaging set—bags, boxes, and labeling—matched to your product.

Customization Options We Offer

Need something unique? We offer full customization to fit your brand’s needs!

Material

PET

Strong and lightweight crystal clearthermoplastic with high-qualityprinting capability.

.webp)

HDPE

Durable, strong tensile strength andlow moisture absorption plastic witha matte finish.

LDPE

Low density, crystal clear plastic withhigh resistance to chemicals.

OPP/CPP

High tensile strength plastic withfood-safe capabilities, made fromrecycled material.

PLA

The green eco-friendly alternative totraditional plastics. PLA isbiodegradable and made fromrenewable resources.

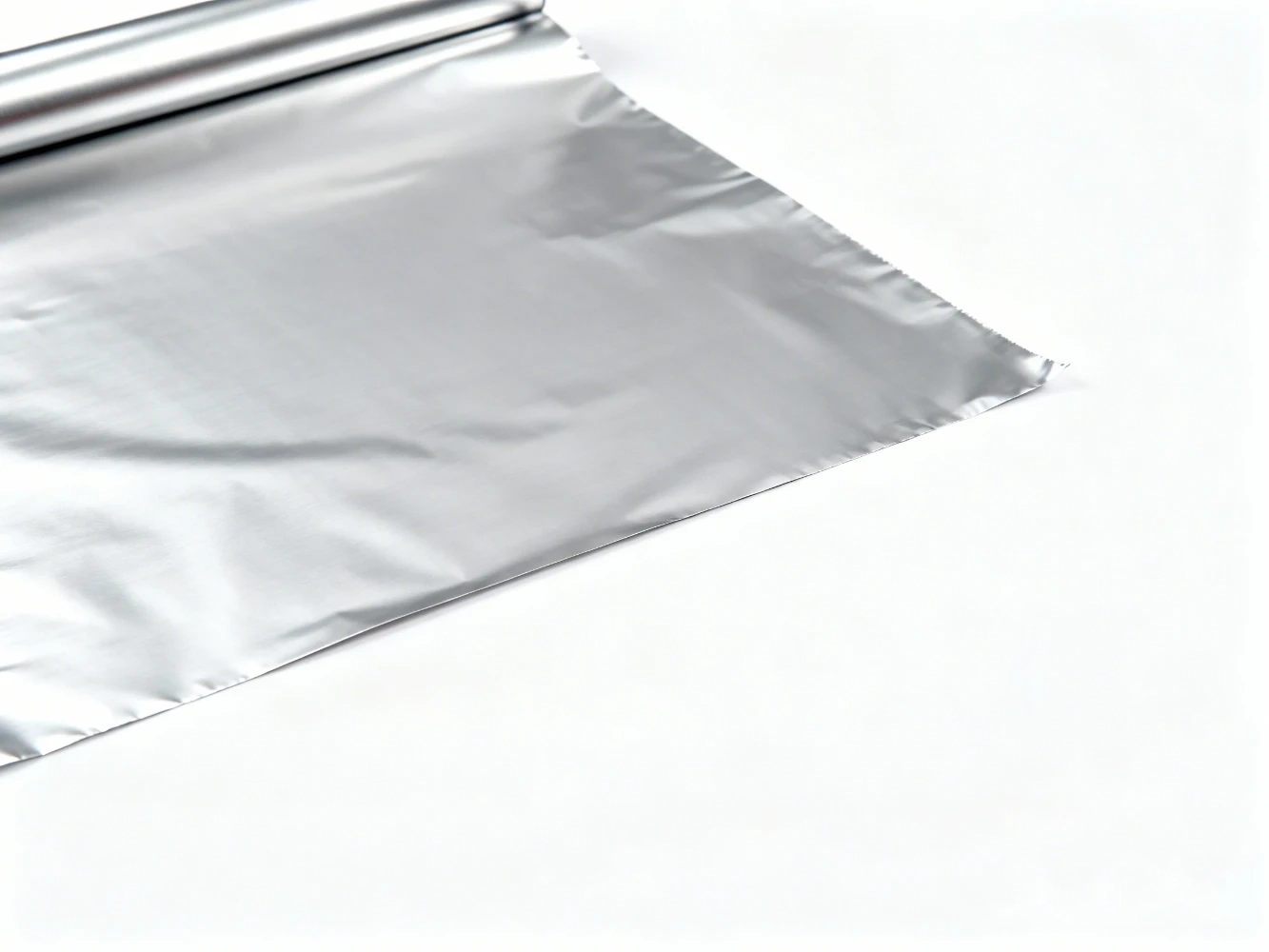

Metallized PET (VMPET)

VMPET is a PET film with an ultra-thin aluminum layer vacuum-deposited on the surface. It offers high barrier against oxygen and moisture, a bright metallic look, and good flexibility when laminated with PE or CPP. Widely used for snack, nuts and cannabis food pouches as a cost-effective alternative to full aluminum foil.

Aluminum Foil (AL)

Aluminum foil is a real metal layer used in high-barrier laminates such as PET/AL/PE. It provides almost complete protection from light, oxygen and moisture, making it ideal for products that require maximum freshness and long shelf life, like coffee, tea and functional powders.

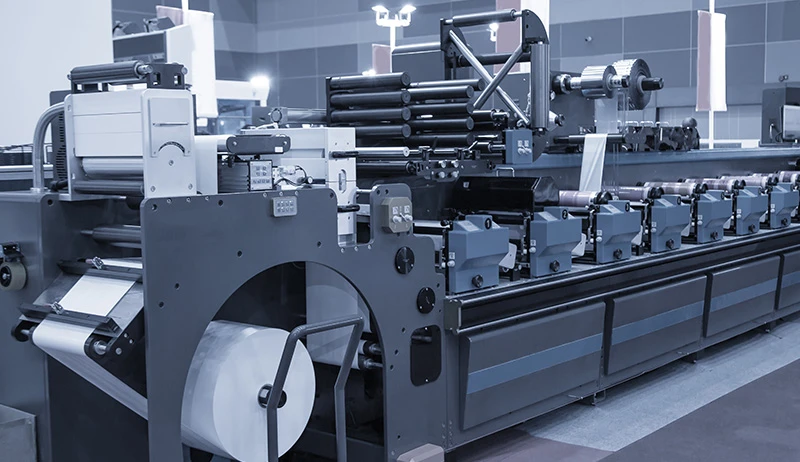

Flexography Print

Quick, economical, moderate-qualityprinting method that utilizes rubberprinting plates to stamp designs onpaper. Best for large runs.

Gravure Print

High-quality printing method thatutilizes a printing plate withmicrocavities to transfer designs onboth paper and plastics.

Offset Print

High-quality printing method thatutilizes a printing plate and rubberblanket to transfer designs on paper.Best for large runs.

Digital Print

Digital printing method that requiresno printing plate. Designs aretransferred electronically, making itcost-effective for small runs.

UV Print

Fast-drying printing method usingultraviolet lights to cure inks whichresults in a gloss finish.

Water-based Ink

100% eco-friendly ink comprised ofwater and pigment that provideshigh-quality color output. Notsuitable for food packaging

Pantone

Pure color based on specific inkformulas to consistenly andprecisely print color.

Soy- ECO

100% eco-friendly ink comprised ofsoy and vegetable oil and pigmentthat provides high-quality coloroutput. Suitable for food packaging.

Pantone Metallic

Metallic color based on specific inkformulas to consistenly andprecisely print color.

Oil Base lnk

Non-eco-friendly ink comprised ofoil and pigment that provides high.quality color output.

Hot Stamping

Hot stamping adds a touch of luxury to packaging, with a metallic shine that instantly elevates the premium feel.

.

Spot Gloss UV

UV coating that is applied to aspecified area and cured usingultraviolet light.

Soft Touch Coating

Soft to the touch coating thatcreates a velvety texture for a moretactile appeal.

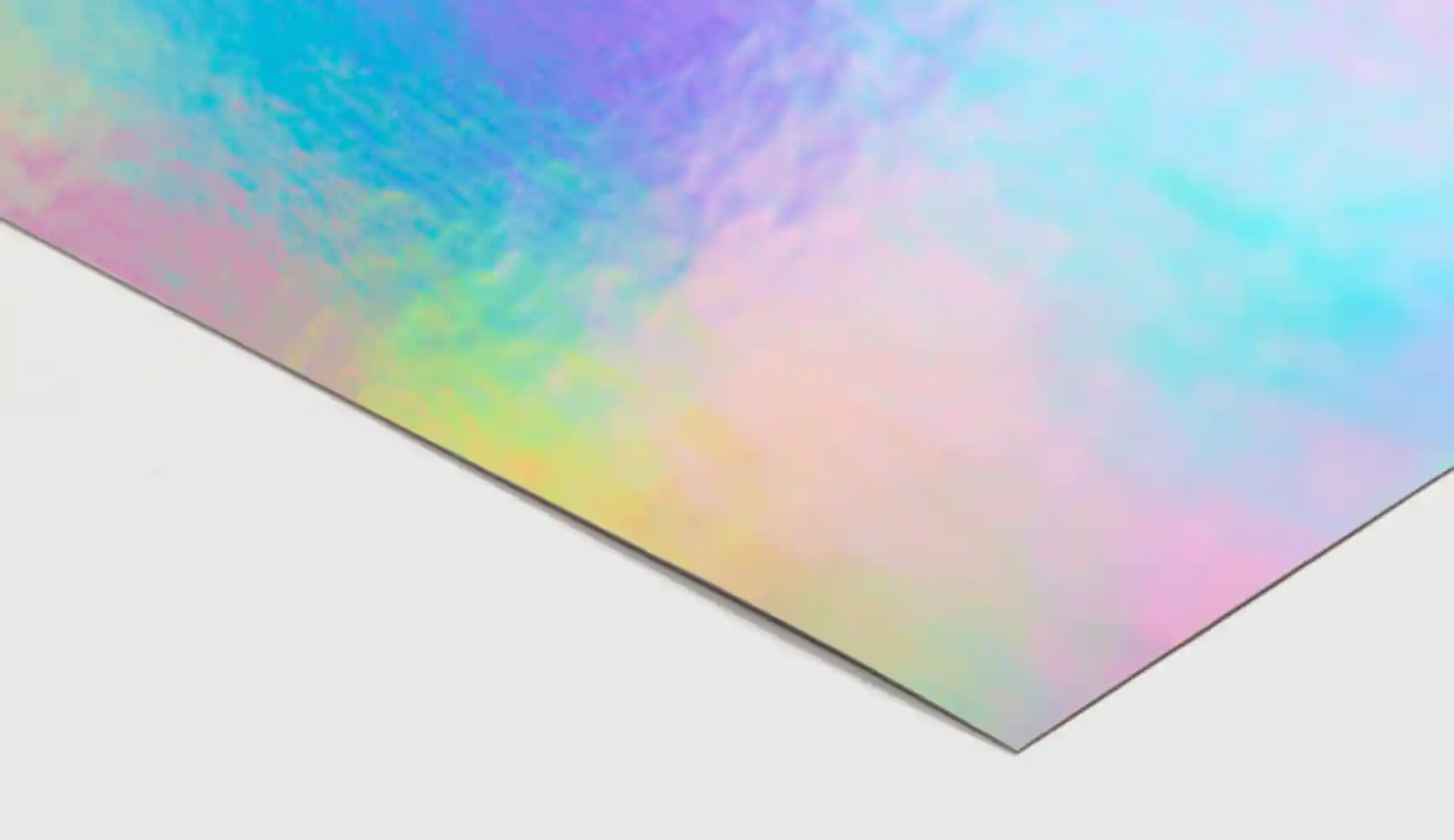

Holographic Effect

Holographic effects create dazzling rainbow colors that shift with light, adding a futuristic and innovative touch.

Matte Finish

Matte finish exudes understated elegance, reducing glare while highlighting refined quality.

Gloss Finish

Gloss finish adds brilliance and vibrancy, making colors pop with eye-catching appeal.

Transparent Window

Transparent windows offer a direct view of the product, building trust and sparking instant desire.

Why Choose Us?

Plant Area

10443㎡

Cooperative Customer

100000+

Annual Order Volume

50000+

Coverage Country

70+

The Voice of Global Customers Is Our Best Business Card

“Absolutely thrilled with my experience with this company🌟 I ordered 500 fully printed zip pouches across 14 SKUs with a soft touch matte finish – and WOW, they turned out incredible! The quality is top-notch: bright, vibrant colours that match my designer’s files perfectly, flawless zipper function, accurate cut lines on every pouch, and not a single reject in the whole order. Tear notches and hang holes are spot on. The thickness is ideal too! Huge shoutout to Quillion, my amazing sales rep, and their design team who helped fix typos and optimize the artwork. I was updated at every step, even receiving printing videos! Despite one box being misdelivered (not their fault), they reprinted and split shipping costs – super supportive even after delivery. Plus, the cost was almost 50% less than local Canadian quotes. Highly recommend – great service, great people, and exceptional results. Will be ordering”

Mia

Canada

“This was my first time ordering custom packaging, so I had a LOT of questions. They were patient with every revision and never made me feel like my order was too small. They helped me choose a pouch size based on my product weight, explained material options in simple terms, and even pointed out how to improve my design margins so text wouldn’t sit too close to the edges. I loved getting photos during production because it kept me calm. Everything arrived on time and looked even better in person. I really appreciate how supportive they were.”

Owen

Spain

“Professional, organized, and scalable.”

Clear process, quick quoting, and easy communication. They confirmed specs clearly and handled changes without drama. This is the kind of supplier you can scale with.

Daniel

USA

“Highly recommend—already planning the next order.”

Top quality, flexible MOQ, and very professional service. I’m not looking for another supplier—this is the team I want to grow with.

Noah

USA

“We had a product launch deadline, so timing mattered more than anything. They gave a realistic production schedule, confirmed every spec quickly, and didn’t overpromise. When we approved the final proof, they started production immediately and sent progress updates every few days. They also confirmed carton packing details and shipping marks so we could track everything easily. The shipment left on time and arrived earlier than expected. I’m very happy because they helped us hit our launch date without last-minute stress.”

Benjamin

Netherlands

“We wanted packaging that looks premium but still fits our budget. They gave us options and explained what impacts cost (material, finish, printing method) without pushing anything unnecessary. We selected a structure that works well for our product, and the final pouches look way better than I expected for the price. Print is clean, zipper is smooth, and the pouch stands well. Very good value and a smooth buying experience.”

Josie

Australia

“Best communication I’ve had with a packaging supplier.”

I’ve worked with several vendors—this was the smoothest. Clear updates, quick answers, and no confusion on specs. The final packaging matched what was promised.

Ethan

U.K.

“Fast turnaround + accurate delivery.”

They gave a realistic timeline, kept me updated, and shipped when they said they would. Packaging arrived earlier than expected and was packed safely.

Sophia

U.K.

“I’ve worked with several packaging suppliers and the biggest issue is usually inconsistency and slow communication. This team is different. The quoting was clear (structure, printing, lead time, packing), and they confirmed everything before production to avoid mistakes. They sent production photos and also confirmed the final carton quantity and packing list details. When the shipment arrived, the quality was consistent across cartons and matched our previous order. That reliability is exactly what we need for ongoing wholesale business.”

Michael

France

“One thing I really appreciated was how transparent they were. They didn’t just say “in production”—they actually sent photos and short videos: printing stage, pouch forming, and final inspection. They also confirmed the final approved proof one more time before starting, which prevented mistakes. This gave me confidence because I knew exactly what was happening. The finished packaging matched the approved design and was delivered on schedule. Highly recommend if you value clear updates.”

Olivia

New Zealand

FAQs · We’ve Got You Covered

We’ve gathered the most common questions from our clients and provided clear answers. Whether you’re a first-time customer or a long-term partner, you’ll find everything you need here to save time and get quick solutions.

What pouch styles do you offer?

We offer stand-up pouches, flat pouches, side gusset bags, quad seal pouches, spout pouches, pillow bags, and shaped die-cut bags.

What pouch styles do you offer?

We offer stand-up pouches, flat pouches, side gusset bags, quad seal pouches, spout pouches, pillow bags, and shaped die-cut bags.

What materials do you recommend for odor and freshness protection?

High-barrier structures and metallized layers help reduce oxygen/moisture ingress and control odors. We’ll match barrier level to your product and shelf-life goals.

How do I choose the right pouch style for coffee or tea?

For coffee and tea, popular options include stand-up pouches, side gusset bags, and quad seal pouches for strong shelf presence and efficient filling. We’ll recommend based on your filling method and target weight.

Can I add a viewing window?

Yes. Windows can showcase the product while keeping key barrier areas protected—layout depends on your product and shelf requirements.

What’s the typical MOQ for custom pouches?

MOQ varies by pouch type, size, and printing. Send your specs and we’ll quote the best available MOQ for your project.

What files do you need to start production?

The artwork is in AI/PDF/PS/JPG/PNG format, with fonts converted to outlines, and includes dimensions, preferred surface finish, and any compliance text requirements.

How do I choose the right pouch size for my product weight?

Share your product type (powder, flower, gummies, coffee, pet food, etc.), target net weight, and approximate density. We’ll recommend a size based on real filling behavior and headspace needs.

What industries commonly use custom pouches besides food?

Custom pouches are widely used for pet food, supplements (non-prescription), cosmetics, household goods, and promotional kits—any product that benefits from lightweight, shelf-ready packaging.

Can you make child-resistant (CR) pouches?

Yes. We offer child-resistant zipper options and can advise suitable formats based on your market requirements and packaging workflow.

What closures can I choose from?

Common options include resealable zippers, tear notches, hang holes, spouts, and heat-seal tops for tamper resistance.

What printing options do you offer?

We support high-quality custom printing suitable for brand colors, fine details, and regulatory text. We’ll recommend the best method based on artwork and quantity.

What materials are best for freshness and barrier protection?

Barrier structures can help reduce oxygen and moisture exposure—key for coffee, tea, snacks, and powdered products. We’ll match the barrier level to your shelf-life goals.

FAQs · We’ve Got You Covered

We’ve gathered the most common questions from our clients and provided clear answers. Whether you’re a first-time customer or a long-term partner, you’ll find everything you need here to save time and get quick solutions.

What box styles can you produce?

We offer mailer boxes, display boxes, folding cartons, lock bottom/auto lock bottom, sleeve boxes, gift boxes, rigid boxes, and more.

Can you use corrugated board for stronger protection?

Yes. Corrugated structures improve compression strength and transit protection—ideal for e-commerce shipping and fragile items.

Do you offer inserts or inner trays?

Yes. We can add paper inserts, molded trays, or custom partitions to secure products and improve unboxing.

Can you print inside the box as well?

Yes. Inside printing is great for brand storytelling, instructions, and compliance messages.

How do boxes ship—flat or assembled?

Many styles ship flat to save freight; rigid boxes usually ship assembled. We’ll recommend the best option for your logistics.

What’s the difference between folding cartons and rigid boxes?

Folding cartons are lighter and efficient for shipping/storage; rigid boxes provide a premium unboxing feel and stronger structure for high-end products.

How do I choose the right box size?

Provide your product dimensions and packing method (single item, set, with insert). We’ll suggest a size with proper clearance and protection.

What finishes can I choose for a premium look?

Options include matte/gloss lamination, spot effects, emboss/deboss, and foil details—chosen based on your design and budget.

What’s your MOQ for custom boxes?

MOQ depends on box style, size, and finishing. Share details and we’ll confirm the best MOQ for your project.

Can you help ensure barcode and regulatory text prints clearly?

Yes. We check placement and print clarity for barcodes, warnings, and batch info based on your market needs.

FAQs · We’ve Got You Covered

We’ve gathered the most common questions from our clients and provided clear answers. Whether you’re a first-time customer or a long-term partner, you’ll find everything you need here to save time and get quick solutions.

Do you offer hot cups and cold cups?

Yes—paper cups for hot drinks and PET cups for iced drinks, with matching lids and accessories.

Are your materials food-grade?

Yes. We use food-contact suitable materials designed for beverage service and delivery scenarios.

What sizes do you offer for coffee and milk tea?

We support common café sizes and can recommend the best capacity based on your menu and serving style.

Do you offer kraft paper bags for takeout?

Yes—paper bags for cafés and retail with options for handles, reinforcement, and different paper weights.

What artwork files do you need for printing?

Vector files (AI/PDF) are best. We’ll confirm bleed, safe margins, and brand color expectations.

What’s the difference between single-wall and double-wall paper cups?

Double-wall improves heat insulation and comfort; single-wall is lighter and often paired with sleeves depending on service needs.

Can PET cups handle condensation and cracking?

We select PET options that resist cracking and deformation, helping cups stay clear and presentable in iced-drink service.

Can you match lids for different cup types?

Yes—flat lids, dome lids, sippy lids, and straw options can be matched to your drink style.

Can your packaging handle delivery and stacking?

We can recommend cup/bag structures designed to perform during busy service hours, transport, and short-term storage.

What’s the typical lead time?

Lead time depends on size, printing, and components (cups/lids/bags). Share your timeline and we’ll propose a practical schedule.

FAQs · We’ve Got You Covered

We’ve gathered the most common questions from our clients and provided clear answers. Whether you’re a first-time customer or a long-term partner, you’ll find everything you need here to save time and get quick solutions.

Can you help with compliance packaging requirements?

Yes. We can support common compliance needs such as clear labeling areas, warning text space, and closure options based on your market.

What packaging is best for flower?

High-barrier pouches with odor control and reliable sealing are commonly used to help preserve aroma and reduce leakage.

Can you provide smell-proof and high-barrier options?

Yes. We offer barrier upgrades (including metallized layers) to better resist oxygen/moisture and help control odor.

Can I include viewing windows?

Yes, and we’ll recommend window placement that balances visibility with barrier needs.

Do you offer tamper-evident options?

Yes. Heat sealing and other closure designs can add tamper evidence and improve shelf confidence.

Do you offer child-resistant solutions?

Yes—child-resistant zipper formats and closure options are available, depending on your packaging style and workflow.

What packaging is best for gummies and edibles?

Food-grade structures with good moisture barriers and reseal features are popular to keep texture and freshness.

Do you support consistent branding across pouches, boxes, and tins?

Yes. We can coordinate print colors, typography, and finishes across formats so your product line looks consistent.

What pouch formats work well for pre-rolls?

Slim pouches, shaped bags, or custom formats are commonly used; closure choice depends on pack count and retail display.

What information should be included on cannabis packaging?

Requirements vary by region, but typically include product identity, net weight, warnings, batch/lot info, and barcode/QR placement. We’ll help reserve space for these elements.

FAQs · We’ve Got You Covered

We’ve gathered the most common questions from our clients and provided clear answers. Whether you’re a first-time customer or a long-term partner, you’ll find everything you need here to save time and get quick solutions.

What’s the difference between stickers and labels?

In practice they’re often the same; we’ll recommend materials/adhesives based on whether you need branding, compliance info, or both.

Do you offer waterproof or oil-resistant labels?

Yes—material choices can improve water, oil, and scuff resistance for food and beverage use.

Can you print barcodes and QR codes clearly?

Yes. We check contrast and sizing guidelines to improve scan reliability.

What is shrink wrap used for?

Shrink wrap can help protect products, reduce tampering, and improve retail presentation for multi-packs or boxed items.

What files do you need for label printing?

AI/PDF is preferred. Please include bleed, safe margins, and any required compliance text.

Can labels withstand refrigeration or condensation?

Yes. We can match label material and adhesive to cold-chain, moisture, and handling conditions.

What finishes are available for labels?

Common options include matte or gloss, clear labels, and premium effects depending on your design goals.

What label shape options do you offer?

Round, square, rectangle, oval, or custom die-cut shapes are all available.

Can shrink wrap fit different product sizes?

Yes. Film size and shrink behavior can be selected to match your product dimensions and packaging line.

How do I choose label material for my product surface?

Tell us the surface type (paper, plastic, glass, metal), storage condition (room temp/fridge), and handling (shipping/rubbing). We’ll recommend a suitable label material and adhesive.